The skateboard wheel is an essential part of the skateboard and is an essential part of the quality and safety of the skateboard. How much do you know about skateboard wheels?

Through this article, skateboard manufacturer Jiesen will share knowledge about skateboard wheels. Let’s take a look together.

What is SHR / HR stand for?

If you are a skateboarding enthusiast, you may have noticed that the word HR or SHR is printed on the skateboard wheels. But do you know what that means?

• HR stands for High Rebound.

• SHR stands for Super High Rebound.

Urethanes with high rebounds are easier to control during power sliding, pivoting, and reversion. A higher rebound also results in fewer flat spots. Therefore skateboards with SHR skate wheels are in a more professional class.

The hardness of skateboard wheels

Skateboard wheels are hardness testers in Durometer Class A.

Longboard wheels are very soft and have a hardness of about 70A.

Skateboard finished wheels range from 95A for a cheap finish to 99A for a high-end finish.

100A is the hardest that can be measured in the A scale of the hardness tester. Therefore, skateboard wheel companies use hardness scale B to make harder wheels.

For example, an 83B wheel is equivalent to 103A. 84B is equivalent to 104A.

Materials for Skateboard Wheels

The primary material used for skateboard wheels is polyurethane, and it is the quality and hardness of the polyurethane that determines the price of the wheel.

The higher the resilience and the more complex the material, the more precise and expensive the material required, and the more complex it is to use the correct urethane mixture. As a result, a set of SHR84B wheels typically costs about four times as much as a set of HR95A wheels to produce.

Professional skateboard wheels are made of professional high-end MDI polyurethane. This polyurethane must be stiff and flexible, soft enough to be still durable when sliding, and it must be consistent enough that you can spin in and out of the pattern without snagging or slipping off. Polyurethane discolors when exposed to air and light, so another critical characteristic skateboard wheel manufacturers look for when mixing polyurethane is color durability. Especially with white skateboard wheels, it is difficult to achieve a color that will not change within the first month of unpacking a new wheel.

In addition to these stringent PU requirements, the production process had to be perfectly calibrated. Temperature, mold filling speed, pressure, and curing time determine the number of air bubbles in the material and the overall final quality of the wheel.

Shapes of skateboard wheels

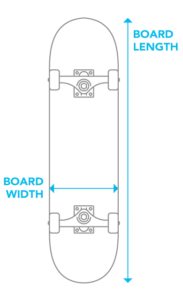

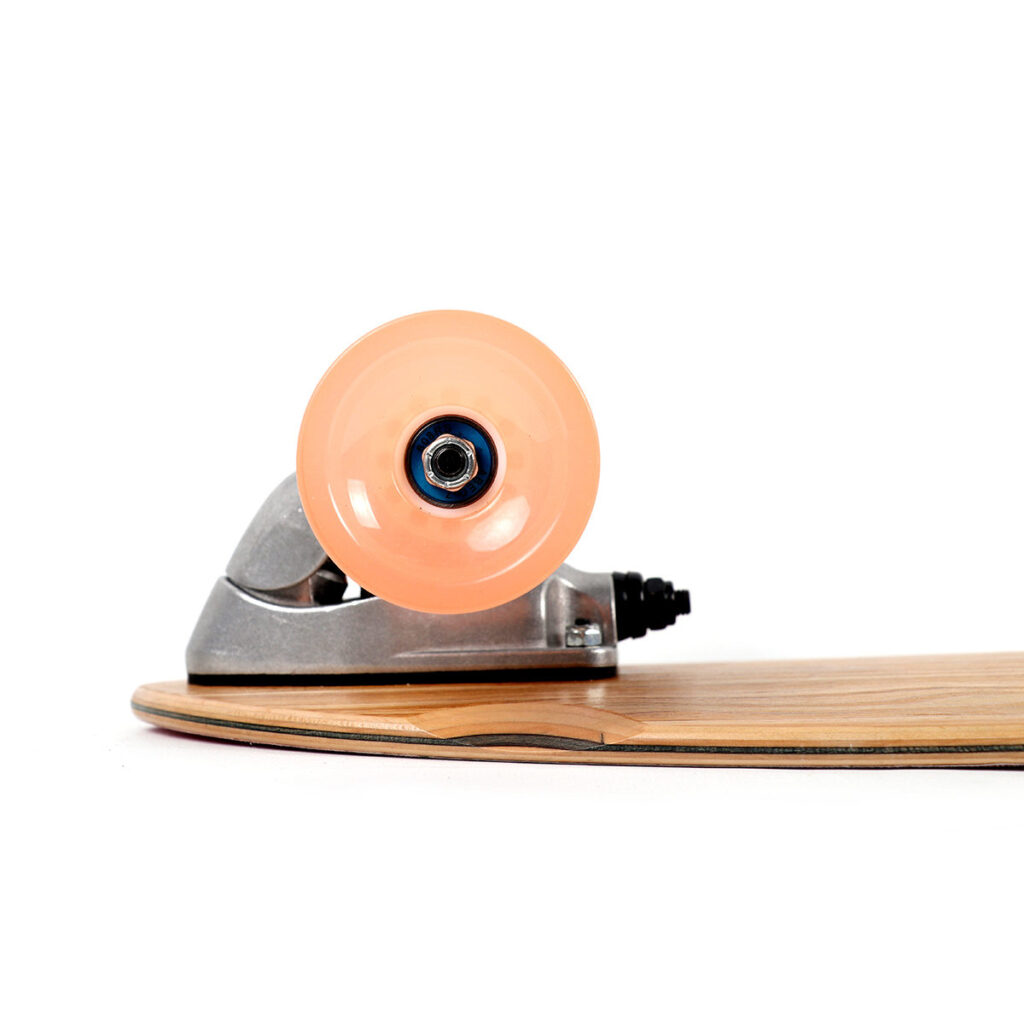

Skateboard wheels come in a variety of shapes. The shape is defined by the total width of the wheel, the width of the contact surface (driving surface) and the side cut.

The most popular wheel brands usually invent various shapes – these shapes then become the market standard and the main reference for most small wheel companies.

The shape of a skateboard wheel is determined by the skateboard wheel mold and cutout. The most professional skateboard wheel molds are made of aluminum and are very precise, requiring little cutting after molding a new wheel. Plastic molds, on the other hand, deform under pressure or when filled with hot molten polyurethane, thus causing the wheels to oscillate. These wheels must then be held in place during the cutting process.

After forming the new wheels, they are fixed to a motor to rotate them at high speed. As they rotate, the wheels are cut into perfect shapes. Wheels made from low quality molds must be cut from all sides to create a rounded shape and clean edges. Wheels from high quality molds can barely be cut – only the threads are added to the contact surface of the wheel because the high quality aluminum mold provides the perfect shape for the wheel from the start.

The contact surface of the wheel is the surface that touches the ground as the wheel rolls. The thread width is usually the same or slightly less than the contact surface. The threads give the rider more grit and control. However, after just one day of skateboarding, these threads have usually come off and are no longer visible.

Production Pricing of Skateboard Wheels

Production pricing for different shapes depends on the quality of the skateboard wheel (material used), whether it can be sold directly from the mold or if the edges must be cut manually, and how many molds of that shape the skateboard wheel factory has (the more molds you have for a particular shape of wheel, the faster the skateboard wheel can be produced).

Printing of skateboard wheels

Print the wheels after they have been molded, baked, cured and cut. This can be done by pad printing or using a digital skateboard printer. Pad printing requires a plate made of plastic or metal. Making plates is expensive and takes a lot of time, but pad printing is fast and inexpensive. Pad printing is therefore best suited for high volume production. If you want less than 200 sets of wheels per design and you need to do it in one day, then a digital printer is the best choice.

Did you get all the above knowledge about skateboard wheels? If you have other questions about skateboard wheels, skateboard related questions, or if you need to order skateboard and related parts, welcome to leave a message or send an email to contact us, professional skateboard manufacturer-Jiesen