Skateboarding is a popular sport and recreational activity millions worldwide enjoy. As the demand for skateboards continues to grow, skateboard manufacturers face the challenge of ensuring consistent product quality. To meet this challenge, these manufacturers employ robust quality control processes to maintain the highest standards in their products. This article will explore the various aspects of how skateboard manufacturers control product quality.

Quality Control Process Overview

Skateboard manufacturers understand the importance of delivering reliable and durable products to their customers. To achieve this, they implement a systematic quality control process involving multiple inspection and testing stages. Let’s take a closer look at each step involved in this process:

Raw Material Inspection

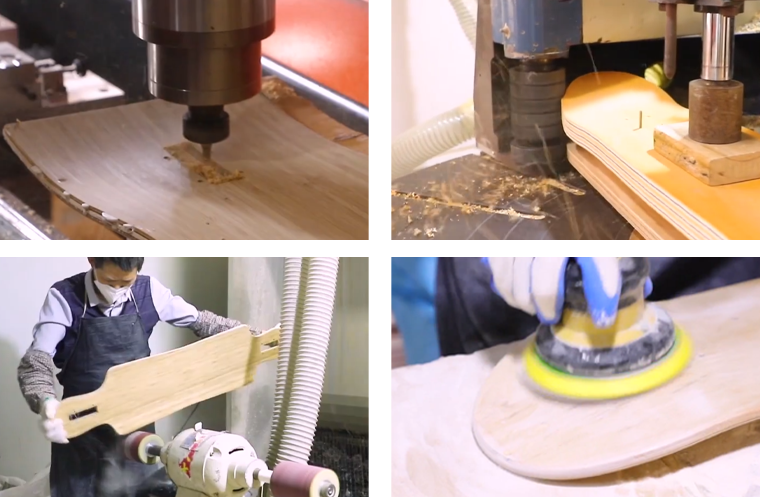

The first stage of quality control begins with the inspection of raw materials. Manufacturers carefully evaluate the quality of wood, grip tape, trucks, wheels, and other components used in skateboard production. Any substandard materials are identified and rejected to ensure only the highest quality materials are used.

Production Line Inspection

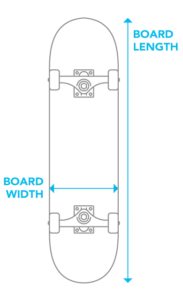

During the production process, manufacturers conduct regular inspections to monitor the quality of skateboards at various stages. This includes checking the accuracy of board shaping, applying grip tape correctly, and ensuring the proper installation of trucks and wheels. Any deviations or defects are identified and rectified promptly to maintain consistent quality.

Performance Testing

Once the skateboards are assembled, they undergo rigorous performance testing. This involves subjecting the boards to simulated riding conditions to evaluate their strength, stability, and overall performance. Manufacturers may use specialized testing equipment or rely on experienced skateboarders to provide valuable feedback on the boards’ performance characteristics.

Safety and Compliance Checks

Skateboard manufacturers prioritize the safety of their customers. They conduct safety checks to ensure their products meet industry standards and regulations. This includes verifying that the boards have appropriate weight capacity, are free from sharp edges, and have adequate grip for riders. Compliance with safety regulations such as ASTM International standards is also considered.

Quality Assurance Sampling

Manufacturers often employ quality assurance sampling techniques to maintain consistency in product quality. This involves randomly selecting a sample of skateboards from a production batch and subjecting them to additional inspections and tests. By analyzing the sample, manufacturers can identify potential issues or deviations from quality standards and take corrective measures if necessary.

Customer Feedback and Warranty Claims

Skateboard manufacturers value feedback from their customers as it provides valuable insights into the performance and durability of their products. They encourage customers to share their experiences and report any issues they encounter. Warranty claims are carefully examined, and patterns of defects or malfunctions are thoroughly investigated to make necessary improvements in the manufacturing process.

Implementing Continuous Improvement

Maintaining high product quality is an ongoing process for skateboard manufacturers. They continually strive for improvement by analyzing quality control processes and customer feedback data. Manufacturers identify areas for enhancement and implement necessary changes in production methods, material sourcing, or design to address quality-related concerns. This commitment to continuous improvement helps manufacturers stay competitive and deliver better products to their customers.

Conclusion

Quality control is an essential aspect of skateboard manufacturing. By implementing a comprehensive quality control process, skateboard manufacturers ensure that their products meet the highest reliability, durability, and safety standards. Manufacturers maintain consistent quality and strive for continuous improvement through raw material inspection, production line checks, performance testing, safety and compliance checks, quality assurance sampling, and customer feedback analysis. Ultimately, these efforts enhance the overall skateboarding experience and rider satisfaction worldwide.